WHO WE ARE

Cyan Fashion is a Dhaka, Bangladesh based Buying House where product development, material sourcing and production are combined under one roof. We have our own fully compliance sewing factory, named Tangon garments ltd and one accessories unit, named S.K Trims, which are operated by Cyan Fashion. We supply a wide range of garments to top European and American markets.

Cyan Fashion was founded by Abu Kayes, a man with a creative mind and huge experience in the garments world. The company began its operations in 2009 in Dhaka, Bangladesh and the sewing factory and accessories unit located at Tongi BSCIC, Gazipur.

Starting with only eight employees, Cyan Fashion currently has 20 staff in its buying house, six hundred in its sewing unit and 30 in its accessories unit. Everybody works with passion and drive to produce world-class quality garments to high-end users.

Cyan Fashion is committed to ethical and sustainable sourcing in every aspect of operations and supply chain management. Our own Factory Tangon garments is BSCI, OEKOTEX, SEDEX and ISO certified.

OUR EXPERTISE

Cyan Fashion success is a result of its Product Development competence. Our extensive customer portfolio shows the level of trust that our customers have in what we do.

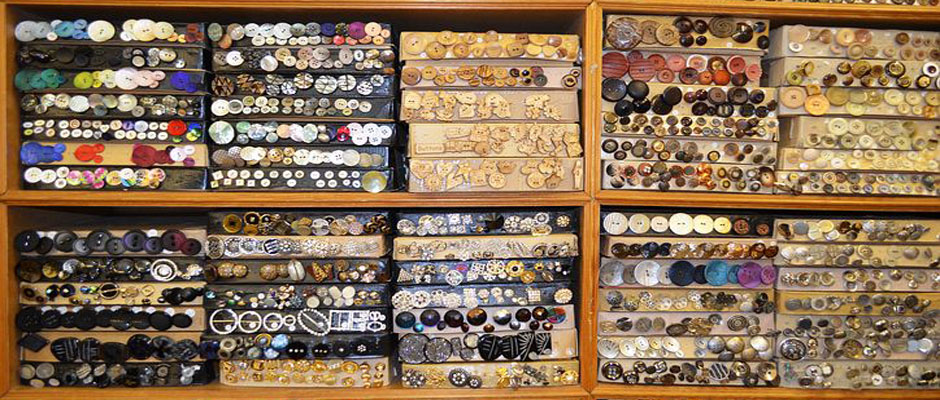

Together with our German Designer we develop products according to the latest trends. To source the right fabrics and accessories and to innovate with different washing and dyeing treatments are essential to the success of Cyan Fashion. We strive to be at the forefront of the latest trends and offer our high profile customers constant inputs as part of new commercial development opportunities.

Cyan Fashion has a fully-fledged samples production unit located within our own premises, featuring specialist machines, cad-cam and boiler. Our pattern makers, supported by highly skilled sewing operators, can produce real time ad-hoc sample products for visiting designers and product developers?

Our Certificate

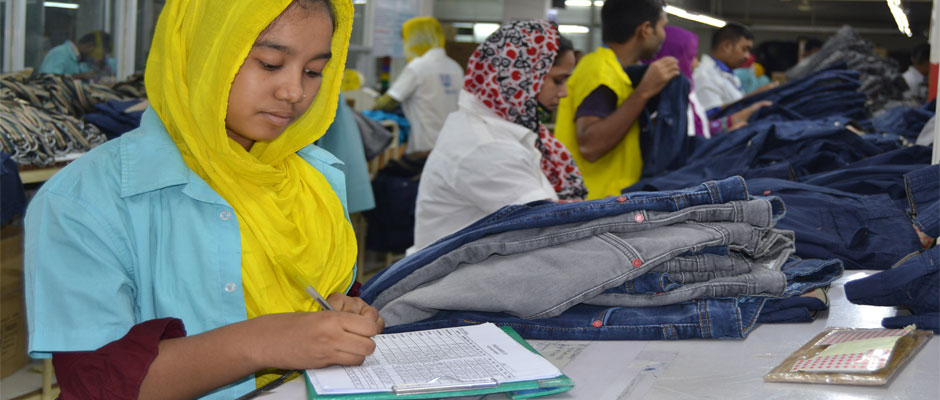

Cyan Fashion has a strong merchandising team who provide the link between the buyer and the factory. Merchandising sub‐groups are created to give effective support to respective buyers to ensure goods are shipped on time. Merchandisers are responsible for sourcing quality fabrics, trims and other relevant elements. They are also responsible for goods clearing and forwarding to the vessel and follow up to arrival at the destinations.

We deliver the quality customers deserve. Pre-production, in-line, final inspections and AQL 2.5 is our everyday business. Our teams are led by experienced technicians who will not only control the quality at the productions sites but also travel and visit our customers to discuss technical developments and possibilities to improve efficiencies. We ensure that all necessary tests of materials are done well in time and with reputable test institutes.

We control the actual outcome of all orders. From the early stage our Quality Assurance starts working on the technical requirements. Before the actual production starts we ensure that each detail is taken well care of. Our Quality Control is on-site and brings attention to detail. With reports measuring the progress and quality of each order we make third party inspections redundant. We provide our partners with the visibility and control needed

.jpg)

.jpg)